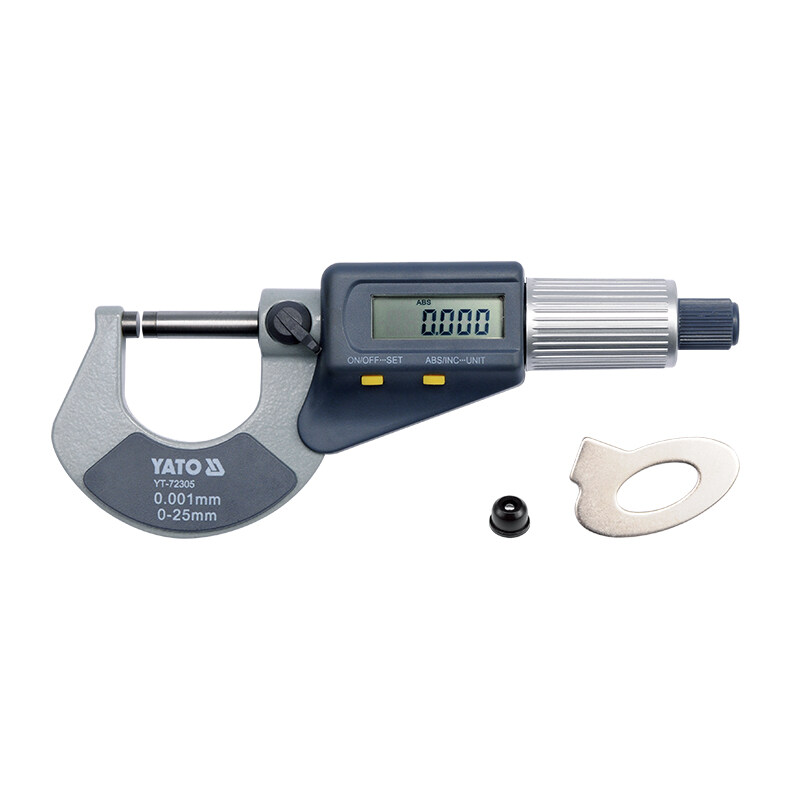

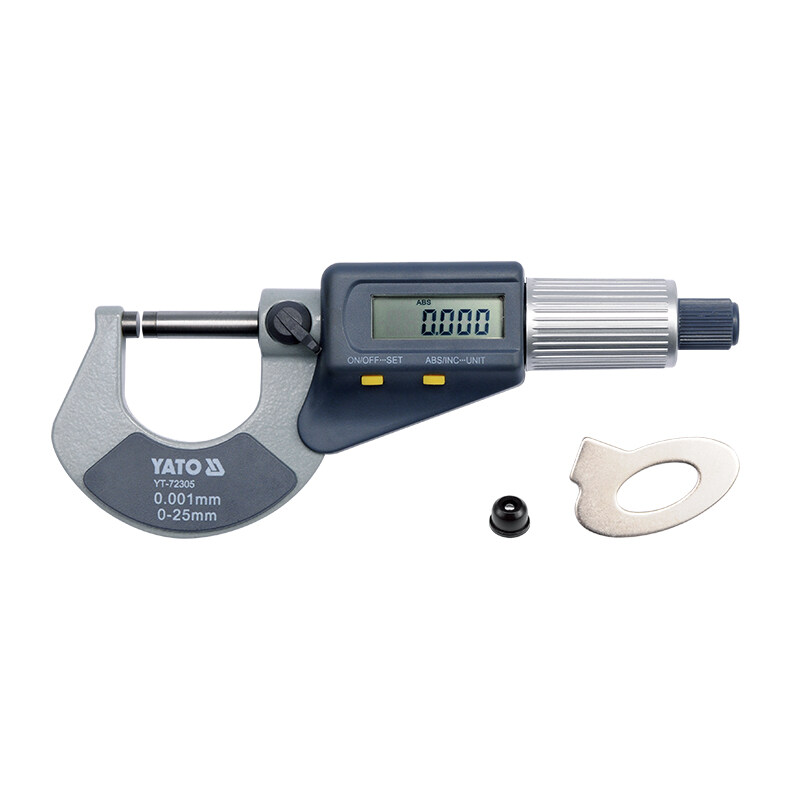

Material

carbon steel, aluminum, PVC

Operating temperature range

Standby power consumption

Specifications Measuring range: 0 - 25 mm

Resolution: 0.001 mm / 0.00005 inch

Accuracy: ±0.002 mm / ±0.0001 inch

Measurement force: 5 - 10 N

Display: LCD display

Current consumption: ≤ 35 μA

Power supply: one silver battery 1.55V, type SR44

Operating temperature: 5OC - 40OC / 41OF - 104OF

Storage temperature: -20OC ÷ 60OC / -4OF ÷ 140OC

Humidity influence: negligible below 80% relative humidity

For precise measurements and easy reading in the range from 0 to 25mm.

Preparation for work:

- Clean the measuring surfaces and guide. Use a cotton cloth for this purpose. Do not use solvents or acids.

- Check the zero position for this purpose, bring the measuring surfaces into contact by turning the friction clutch knob only. Then press and hold for approx. button labeled ON/OFF•••SET” for 2 seconds until the indication is reset.

- Check that all buttons, switches and display function properly. Basic measurement methods: 1. Absolute measurement - Loosen the retaining clamp.

-Turn on the device by pressing the "ON" button. Select the measurement unit by pressing and holding the "ABS/INC•••UNIT" button for approx. 2 seconds. Each time the measurement result will alternately be displayed in inches or millimeters. The result in inches is indicated by the "in" symbol on the display screen. Press the "ABS/INC•••UNIT" button until the "ABS" symbol appears on the display.

- Separate the measuring surfaces a little further than the object to be measured.

- Then, by rotating the spindle knob, set the coarse then continue tightening by turning the friction clutch knob. Stop tightening when clutch engages.

- Read the measurement result from the display. 2. Relative measurement The principle of measurement corresponds to that described above, but relative measurement is used to compare two dimensions.

- When pressing the "ABS/INC•••UNIT" button, the indication will be reset and the display will show "INC". After re-measuring, you can read the difference in dimensions. The micrometer is equipped with a steel ball in a rubber mount for mounting on the measuring surface of the micrometer. It facilitates the measurement of elements with a small area. After inserting it, reset the indication according to the procedure described above.

Attention!

It is recommended to mount the item to be measured or the micrometer before starting the measurement. This will allow you to achieve the highest measurement accuracy. It is also recommended to carry out several measurements in order to obtain the arithmetic mean of the results.